The C18 rediscovery/ re-invention of concrete . . . it had apparently been made by the Romans, Greeks and Egyptians [–> earlier, the Nabataeans] (and many natural, volcanic or sedimentary rocks are concrete-like) . . . opened up a world of new building possibilities; especially, when it is reinforced by steel. As, we can see all around us.

But, concrete here uses a high energy process based on limestone, so how can we break through such barriers for the Moon or Mars? And, how could this be relevant to our home world, Earth?

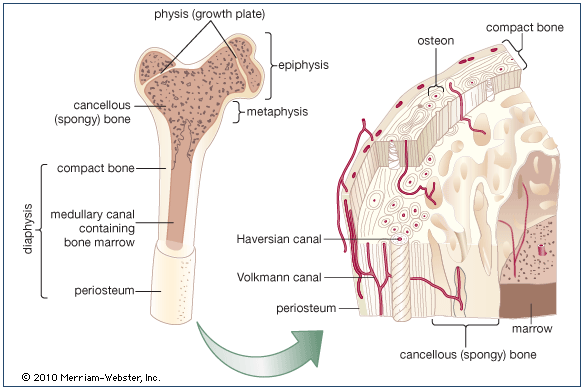

We could look at bones and teeth. For:

>>The minerals found in human teeth and bones that give them their hardness and strength belong to a group of minerals called biological apatites . . . . Tooth enamel is the hardest and most highly mineralised substance in the body. It is 96% mineral, with water and protein accounting for the other 4%. This high mineral content gives it strength and hardness, but also brittleness . . . . Dentine is found just under the enamel in the crown of the tooth and under the cementum in the root. It determines the size and shape of tooth.

Like enamel, it is a hydroxyapatite, but with a slightly different composition. The unique structure and composition of dentin allows it to function as the substructure for rigid enamel tissue. This provides teeth with the ability to flex and absorb tremendous forces without fracturing . . . .

[Science Learning Hub, NZ]

Bone is a specialised form of connective tissue. It is composed of cells embedded in a mineralised mixture of collagen fibres, bone proteins and carbohydrate-based chemicals called glycans.>>

In short, bones and teeth are based on smart composites, with rock-like minerals set in a protein-based polymer matrix, similar to asphalt or fibreglass or . . . concrete, but essentially at molecular level. The light bulb in the thought-bubble should be going on. First, the challenge:

>>[I]f humans actually do reach Mars, or even establish settlements on the moon, they would need thousands of tons of concrete to survive. That’s because both Mars and the moon are bombarded constantly with both lethal radiation and micrometeorites that would quickly punch holes into any ordinary structure. Since it’s impossible to ship tons of cement from Earth to Mars, the best bet is for humans to start making it when they arrive.

[“A new technique could help turn Mars or moon rocks into concrete,” Edmund Andrews, Stanford, May 2, 2017]

The problem is that making Earth-style concrete requires tremendous amounts of heat and energy, because you have to cook limestone to create the binding agent that holds concrete together. For the first human outposts on Mars, energy will be in very short supply . . . >>

Notice, a familiar energy-materials, Malthusian resources challenge.

To solve it, NASA engineers reached out to a Stanford researcher, Michael Lepetch, who has been exploring low energy concrete alternatives based on protein-mineral matrices. Get thee behind me, Thomas Malthus!

(And BTW, according to the same article, “NASA would like to send humans to Mars by 2030. Elon Musk, the CEO of SpaceX, says his private launch company could do it as early as 2024.” That’s a Moon-shot, decade length, we choose to do it because it is hard, timeframe.)

The suggested solution, as Andrews explained:

>>In search for a less energy-intensive alternative, Loftus and Lepech turned to biology. Living organisms use proteins to make things as tough as shells, bones and teeth, so the researchers began working on a concrete bound together with a protein from bovine blood. The protein is a fairly cheap by-product of slaughterhouses, and it is known to become very gluey when mixed with soil.

To replicate the conditions on Mars and the moon, Lepech has combined the protein with simulated extraterrestrial soils that are similar to what’s on Mars and the moon. And because Mars has much lower gravity than Earth – bad for cement mixing – the researchers did their mixing with a vacuum technology that is used to make the composite materials in products such as boat hulls.

Sure enough, the first batch was as strong as the concrete used for sidewalks and patios – a good start. It also held up well to a simulated bombardment of micrometeorites, which the researchers replicated by taking the material to the Ames Vertical Gun Range and blasting it with high-speed gas particles.

For the purposes of making concrete on Mars, the idea is to create biological “factories” of organisms that are genetically engineered to produce the protein binder. It’s the same way that biotech companies use genetically engineered bacteria to make synthetic hormones. The feedstock for those organisms would come from the settlement’s recycled organic waste.>>

There is a challenge for our home world, however, as heavy rains will degrade the present formulation over a few years. To solve it, they hope to tweak the proteins, and to become more efficient in production. Sort of reminds us that some woods decay easily, others, not so much.

So, we are looking at possibilities for low energy cost construction that in effect binds dirt together with particles, forming concrete.

Get thee behind me, Malthus! END